Wago

281-612

1 / 1

- Part Number

- 281-612

- Tariff Code

- 85369095000

- UPC

- 4045454871482

- ETIM

- Group Code : EG000012

- Group Description : Terminal blocks

- Class Description : Fuse terminal block

- Class Code : EC000899

- Version : 7

- Get up to 90 days payment terms from 500+ suppliers

- Reselling discounts up to 40%!

Send request for price

1

Payment methods:

Ratings Per Iec/En

- Ratings per

- IEC/EN 60947-7-3

- Ratings (note)

- Electrical ratings are given by the fuse.

- Nominal voltage (III/3)

- 800 V

- Rated impulse voltage (III/3)

- 8 kV

- Rated current

- 10 A

- Operation status indicator

- None

- Legend (ratings)

- (III / 3) ≙ Overvoltage category III / Pollution degree 3

Environmental Requirements

- Processing temperature

- -35 … +85 °C

- Continuous operating temperature

- -60 … +105 °C

Physical Data

- Width

- 8 mm / 0.315 inches

- Height

- 60 mm / 2.362 inches

- Depth from upper-edge of DIN-rail

- 60 mm / 2.362 inches

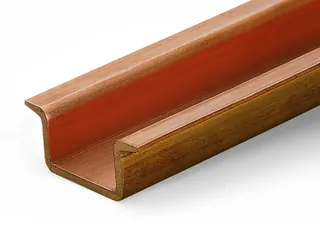

Material Data

- Note (material data)

- <a href="https://www.wago.com/us/material-specifications" href="_blank">Information on material specifications can be found here</a>

- Color

- Gray

- Material group

- I

- Insulation material

- Polyamide (PA66)

- Flammability class per UL94

- V0

- Fire load

- 0.318 MJ

- Weight

- 16.956 g

Mechanical Data

- Design

- Angled

- Mounting type

- DIN-35 rail

- Marking level

- Center marking

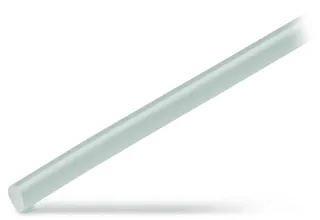

General

- Fuse receptacle

- Pivoting

- Fuse type

- Cylindrical fuse; 5 x 25 mm

Specifications

- Product Group Code

- 0001

Commercial Data

- Packaging type

- Box

- Country of origin

- IN

- GTIN

- 4045454871482

- Customs tariff number

- 85369095000

Power Loss

- Power loss (max.) Pl (max.) (note)

- When selecting glass cartridge fuses, make sure that the maximum power loss listed below is not exceeded. The power loss is determined according to IEC or EN 60947-7-3/VDE 0611-6 at 23°C. The temperature rise of the terminal block must be checked according to their application and mounting. Higher ambient temperatures represent an additional impact on miniature fuses. Therefore, in such applications, the rated current must be reduced if necessary. More details are available from the manufacturers.

- Power loss Pl max. overload and short-circuit protection (individual arrangement)

- 2.5 W

- Power loss Pl max. overload and short-circuit protection (group arrangement)

- 1.6 W

- Power loss Pl max. short-circuit protection (individual arrangement)

- 4 W

- Power loss Pl max. short-circuit protection (group arrangement)

- 4 W

Connection 1

- Connection technology

- CAGE CLAMP®

- Actuation type

- Operating tool

- Connectable conductor materials

- Copper || Aluminum

- Connectable conductor materials (note)

- Terminating Aluminum ConductorsWAGO spring clamp terminal blocks are suitable for solid aluminum conductors up to 4 mm²/12 AWG if WAGO “Alu-Plus” Contact Paste <a href="https://www.wago.com/249-130">249-130</a> is used for termination.“Alu-Plus” Contact Paste Advantages:Automatically destroys the oxide film during clamping.Prevents fresh oxidation at the clamping point.Prevents electrolytic corrosion between aluminum and copper conductors (in the same terminal block).Provides long-term protection against corrosion.Using terminal blocks with CAGE CLAMP® Spring Pressure Connection Technology, aluminum conductors must first be cleaned with a blade and then immediately be inserted into the clamping units filled with “Alu-Plus” Contact Paste.It is also possible to apply WAGO “Alu-Plus” additionally on the whole surface of the aluminum conductor before termination.Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors::2.5 mm² = 16 A4 mm² = 22 A

- Solid conductor

- 0.08 … 4 mm² / 28 … 12 AWG

- Fine-stranded conductor

- 0.08 … 4 mm² / 28 … 12 AWG

- Strip length

- 9 … 10 mm / 0.35 … 0.39 inches

- Wiring direction

- Front-entry wiring