Wago

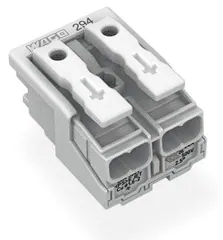

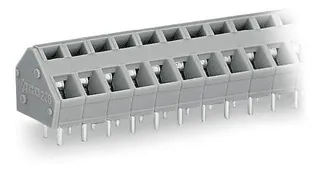

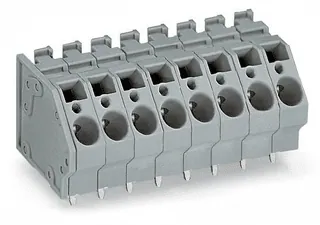

773-124

1 / 2

- Part Number

- 773-124

- Tariff Code

- 85369010000

- UPC

- 4044918397834

- ETIM

- Group Code : EG000047

- Group Description : Installation, isolation and connection material

- Class Description : Screw less terminal

- Class Code : EC000446

- Version : 7

- Get up to 90 days payment terms from 500+ suppliers

- Reselling discounts up to 40%!

Send request for price

1

Payment methods:

Ratings Per Iec/En

- Ratings per

- IEC/EN 60664-1

- Nominal voltage (II/2)

- 400 V

- Rated surge voltage (II/2)

- 4 kV

- Rated current

- 24 A

- Legend (ratings)

- (II / 2) ≙ Overvoltage category II / Pollution degree 2

Environmental Requirements

- Continuous operating temperature

- 105 °C

Physical Data

- Width

- 13 mm / 0.512 inches

- Height

- 13.1 mm / 0.516 inches

- Depth

- 19.5 mm / 0.768 inches

Material Data

- Note (material data)

- <a href="https://www.wago.com/us/material-specifications" href="_blank">Information on material specifications can be found here</a>

- Color

- Multicoloured

- Cover color

- Light gray

- Flammability class per UL94

- V2

- Fire load

- 0.058 MJ

- Weight

- 2.772 g

Specifications

- Product Group Code

- 0007

Commercial Data

- Packaging type

- Box

- Country of origin

- DE

- GTIN

- 4044918397834

- Customs tariff number

- 85369010000

Notes

- Safety information

- In grounded power lines

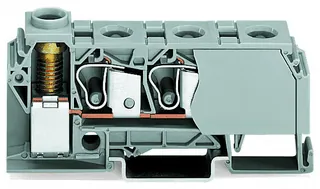

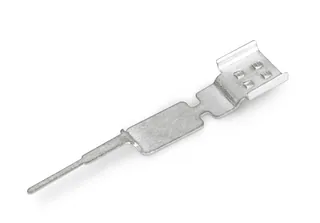

Connection 1

- Connection technology

- PUSH WIRE®

- Actuation type

- Push-in

- Connectable conductor materials

- Copper || Aluminum

- Connectable conductor materials (note)

- Terminating Aluminum ConductorsWAGO spring clamp terminal blocks are suitable for solid aluminum conductors up to 4 mm²/12 AWG if WAGO “Alu-Plus” Contact Paste <a href="https://www.wago.com/249-130">249-130</a> is used for termination.“Alu-Plus” Contact Paste Advantages:Automatically destroys the oxide film during clamping.Prevents fresh oxidation at the clamping point.Prevents electrolytic corrosion between aluminum and copper conductors (in the same terminal block).Provides long-term protection against corrosion.For spring clamp connections with PUSH WIRE® connection technology, WAGO recommends that the aluminum conductor first be cleaned and then immediately inserted into the clamping unit filled with “Alu-Plus” contact paste.It is also possible to apply WAGO “Alu-Plus” additionally on the whole surface of the aluminum conductor before termination.Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors::2.5 mm² = 16 A4 mm² = 22 A

- Solid conductor

- 0.75 … 2.5 mm² / 18 … 12 AWG

- Stranded conductor

- 1.5 … 2.5 mm² / 16 … 12 AWG

- Fine-stranded conductor

- 0.75 mm² / 18 AWG

- Strip length

- 12 mm / 0.47 inches

- Wiring direction

- Side-entry wiring

Other Categories

ActuatorsBlocksCables, Pipes & HosesCompressorsControlCouplings & FittingsCylinders & PistonsElectronicsFiltersHVACIndustrial PC's & HMIsLightingLinear techniqueMotorsPower SupplyPower TransmissionPumps & ValvesRenewable energyRoboticsSeals, Rings & ConnectorsSensors & Measuring DevicesTools and AccessoriesCNCOther